Die Casting in Malaysia: Precision Manufacturing for a Competitive Edge

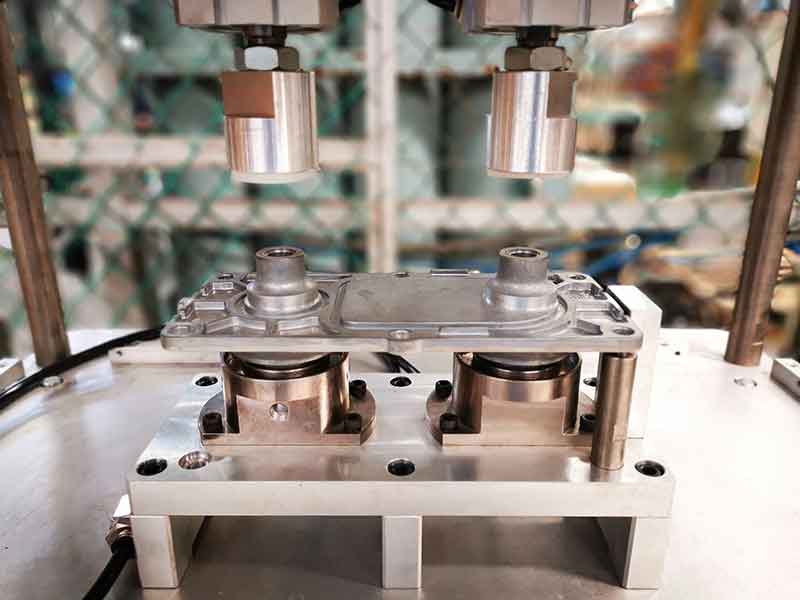

Die casting is an essential manufacturing process, supplying precision and durability to a variety of industrial processes. In Malaysia the process of die casting is now a major industry, supporting sectors like electronics, automotive construction, as well as consumer products. Die casting involves forcing hot metal into a cavity at high pressure, making intricate and top-quality products. Malaysian firms that specialize in die casting are renowned for their advanced techniques, innovative technologies, and commitment to quality, creating a regional center for the development of precision engineering. With a focus on efficiency and sustainability, die casting is a major part of Malaysia continues to evolve which is a major contributor in the development of Malaysia's industry.  One of the main motives behind the widespread use of the process in Malaysia is its effectiveness in producing complex shapes with minimal materials waste. Die casting allows companies to develop intricate designs as well as light parts without losing durability or the quality. Aluminium, zinc and magnesium are the most commonly used metals in die casting, with each offering unique benefits for specific applications. Aluminum, for instance, is favored for its excellent strength-to-weight ratio. This makes it ideal for automobile as well as aerospace components. This ability to tailor techniques and materials to meet requirements of the industry has placed Malaysia as an industry leader on the international market for die casting. Malaysia's strategic location and well-developed infrastructure have created a favorable environment for die casting companies looking to serve both the international and regional markets. Malaysia has state of the art manufacturing facilities as well as a highly skilled workforce which allows manufacturers to comply with the stringent quality standards required for industries like automotive or electronic industries. Furthermore, Malaysia's strong supply chain and accessibility to raw materials will ensure production timelines are optimized, helping manufacturers maintain an edge in the market. The growth in exports has been an important factor, with Malaysian die casting companies providing high-quality components to markets in Asia, Europe, and the Americas. Sustainability is becoming an integral focus for die casting companies in Malaysia and is aligned with international efforts to lessen the environmental impact. Many manufacturers are adopting eco-friendly methods like recycling materials from scrap and utilizing energy-efficient machinery. Materials that are lightweight, such as magnesium and aluminum are increasingly being used in die casting, contributing to the creation of parts that help reduce energy use in end products, like vehicles. Through a focus on sustainable practices, this Malaysian die casting industry is a part of environmentally-friendly goals, as well as the growing demand for green manufacturing solutions. This commitment enhances the industry's popularity with eco-conscious customers and partners. To get new details please Visit Website

One of the main motives behind the widespread use of the process in Malaysia is its effectiveness in producing complex shapes with minimal materials waste. Die casting allows companies to develop intricate designs as well as light parts without losing durability or the quality. Aluminium, zinc and magnesium are the most commonly used metals in die casting, with each offering unique benefits for specific applications. Aluminum, for instance, is favored for its excellent strength-to-weight ratio. This makes it ideal for automobile as well as aerospace components. This ability to tailor techniques and materials to meet requirements of the industry has placed Malaysia as an industry leader on the international market for die casting. Malaysia's strategic location and well-developed infrastructure have created a favorable environment for die casting companies looking to serve both the international and regional markets. Malaysia has state of the art manufacturing facilities as well as a highly skilled workforce which allows manufacturers to comply with the stringent quality standards required for industries like automotive or electronic industries. Furthermore, Malaysia's strong supply chain and accessibility to raw materials will ensure production timelines are optimized, helping manufacturers maintain an edge in the market. The growth in exports has been an important factor, with Malaysian die casting companies providing high-quality components to markets in Asia, Europe, and the Americas. Sustainability is becoming an integral focus for die casting companies in Malaysia and is aligned with international efforts to lessen the environmental impact. Many manufacturers are adopting eco-friendly methods like recycling materials from scrap and utilizing energy-efficient machinery. Materials that are lightweight, such as magnesium and aluminum are increasingly being used in die casting, contributing to the creation of parts that help reduce energy use in end products, like vehicles. Through a focus on sustainable practices, this Malaysian die casting industry is a part of environmentally-friendly goals, as well as the growing demand for green manufacturing solutions. This commitment enhances the industry's popularity with eco-conscious customers and partners. To get new details please Visit Website  The growth of Malaysia's die casting industry is supported through government-sponsored initiatives that aim at fostering innovation and investment. Strategies that encourage research and development as well as incentives for technology adoption, have strengthened this sector. Collaborations between industry players as well as academic institutions guarantee an ongoing supply of highly skilled experts with the most recent technology. Additionally, Malaysia's strategic location and its trade agreement has made it a hub for export-oriented manufacturing. The supportive environment has allowed die casting firms to expand their operations as well as increase their capabilities. It is ensuring that their contribution to Malaysia's manufacturing growth will be substantial. Die casting in Malaysia shows the nation's commitment to precision, innovation, and sustainability in the manufacturing. Through the use of advanced technology, skilled talent, and environmentally conscious techniques, the business serves as a cornerstone of the Malaysian industrial environment. From automotive components to electronic consumer products, the flexibility and durability of die casting make it indispensable across multiple sectors. As the global demand for durable, top-quality manufacturing options grows, Malaysia's die casting industry has the potential to be a leader, enhancing its reputation as a hub of innovation and excellence. With constant innovation and a constant focus on quality, die-casting in Malaysia will undoubtedly remain a vital driver of industrial progress.

The growth of Malaysia's die casting industry is supported through government-sponsored initiatives that aim at fostering innovation and investment. Strategies that encourage research and development as well as incentives for technology adoption, have strengthened this sector. Collaborations between industry players as well as academic institutions guarantee an ongoing supply of highly skilled experts with the most recent technology. Additionally, Malaysia's strategic location and its trade agreement has made it a hub for export-oriented manufacturing. The supportive environment has allowed die casting firms to expand their operations as well as increase their capabilities. It is ensuring that their contribution to Malaysia's manufacturing growth will be substantial. Die casting in Malaysia shows the nation's commitment to precision, innovation, and sustainability in the manufacturing. Through the use of advanced technology, skilled talent, and environmentally conscious techniques, the business serves as a cornerstone of the Malaysian industrial environment. From automotive components to electronic consumer products, the flexibility and durability of die casting make it indispensable across multiple sectors. As the global demand for durable, top-quality manufacturing options grows, Malaysia's die casting industry has the potential to be a leader, enhancing its reputation as a hub of innovation and excellence. With constant innovation and a constant focus on quality, die-casting in Malaysia will undoubtedly remain a vital driver of industrial progress.